Gold Leaf Maximizer®

The Maximizer® is a revolutionary device that increases energy efficiency and reduces emissions from carbon-based fuels.

With its unique and proprietary monopolar fluid treatment system, this patented solution is superior in performance, sustainability and value compared to any similar device on the global market today.

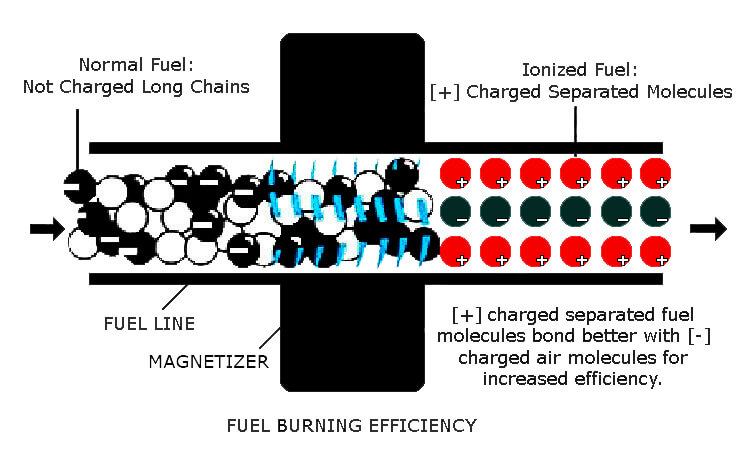

The Maximizer technology separates the fuel molecules just prior to combustion, allowing a substantial increase of oxygen molecules to be added. This reaction then leads to a cleaner burn of fuel, higher efficiency overall and lower consumption of fuel.

The Maximizer has been successfully installed on natural gas, propane, diesel oil, and gasoline-burning equipment. Additional tests have been done in relation to significant increases in combustion temperatures achieved. The application is non-invasive and chemical-free, requires no power source or retrofit, and can be quickly installed with no shutdown or disruption.

Tests, evaluations and testimonials from leading engineering teams and thousands of users worldwide can attest to the Maximizer’s success in helping companies and organizations manage their energy consumption, strengthen their performance, and save money on fuel costs.

THE WHY OF OUR BUSINESS

The concerted effort to “go green” has been felt across industries, as companies are beginning to realize how their operations impact the environment. What motivates us is the belief that, with the Maximizer technology, we’re playing an important role on the world market, by contributing to a greener, better world.

THE HOW OF OUR BUSINESS

We have years of experience related to the manufacturing process, as well as the proper installation techniques and supply chain logistics, that allow us to reach clients worldwide with seamless quality control, technical support, and turnaround time.

Return on Investment

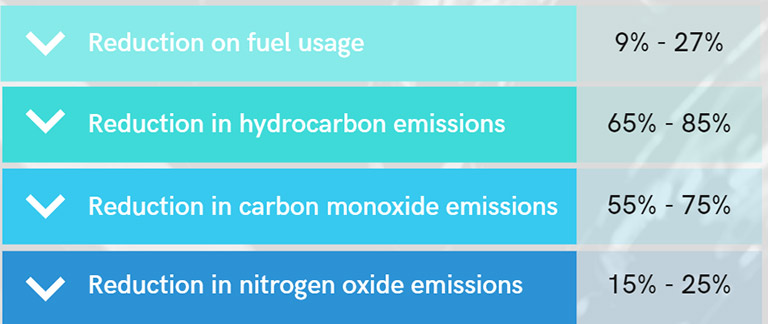

Reduce fuel spend and consumption by 9-27% every year, with an energy savings payback of two years or less. Lower carbon monoxide and hydrocarbon emissions by 60%+ and nitrogen oxide emissions by 10%+. In many cases, the results are greater.

What makes us stand apart from our competition?

- Unrivaled performance and efficiency. The Maximizer’s conditioning of fuel is more efficient than other methods on the market. The technology also separates hydrocarbon molecules better and longer.

- Exceptional quality of its components. Maximizer application uses high density magnets, dipped in a high-grade plastisol for a superior surface durability in all weather conditions. They are special ceramic alloys, whose strength does not decrease over time. This means a one-time investment in Maximizer for the life time of buildings or equipment.

- Proven technology. Maximizer technology is mature, has been honed over the years, and is offered in the optimal design and efficiency as a line of over 60 fuel saving and emission control systems. It received its first patent in 1985 and has successfully entered global markets non-stop since the 90’s.

- Proven performance. The Maximizer has been installed in hundreds of commercial and industrial sites around the world, boasting significant results. Some users include: IBM, Siemens, Toyota, Subaru, Sapporo, Hilton, Yamaha, Bosch, Mitsubishi Electric, Nippon Steel, and Marriot.

World-Class Companies Choose The Maximizer®

How Does the Maximizer Work?

The Maximizer energizes, organizes and polarizes random and clustered fuel molecules by:

- giving them a permanent dipole moment;

- changing their electron spin and hydrogen’s isomeric para-hydrogen form to a more volatile (combustible) ortho-hydrogen; and

- giving them an extremely strong and focused charge (positive or negative), which breaks clusters (hydrocarbon associates) apart and organizes their molecular structure.

Then, it attracts ionically oxygen atoms to the hydrocarbon molecule and create better oxygen bonding and better fuel oxidation.

Para- to ortho-conversion destabilizes the long molecules which break up easily, become ionized and atomized, and show reduced viscosity and surface tension. That means downstream in the Maximizer, smaller species of hydrocarbons are found. Reduced surface tension is a consequence of reduced intermolecular forces. It means smaller molecules. Also para- to ortho- conversion results in the reduction in viscosity and surface tension. These are measurable parameters which have been confirmed by science to be reduced.

By applying a properly-focused magnetic field to ionize fuel to be fed to a combustion chamber, we can ensure a more complete combustion process. This, in turn, can maximize fuel economy, improve fuel efficiency and reduce polluting emissions.

The air and fuel are subject to the lines of forces from permanent magnets mounted on the air and fuel inlet lines. The magnet for producing the magnetic field is positioned so that its South Pole (red colour systems) is located adjacent to the fuel line and its North Pole (blue) is located spaced apart from the fuel line. The magnetic field strength must be at a properly-selected Gauss level since it may get demagnetized to some extent before reaching the combustion chamber.

There’s no secret as to the effectiveness of the Maximizer monopolar fluid treatment system. It produces order from chaotic molecular behaviour, with a predominate single charge ion. Fluids are not only imbued with magnetic properties.

What occurs with fluids when the Maximizer is employed is that hydrogen nuclei lose their random alignment and align as charge separated molecules, reducing the size and changing the form, producing all of the benefits described on this site for each application.

Apart from the resonant excitation of a fluid flowing through the magnetic field there take place the following phenomena and changes: whirling of trajectories of charged and diamagnetic particles, selective ionization, circulatory eddy currents, electric and magnetic fields, changes in the speed and pressure profile, as well as the electrical conductivity of liquids.

Also, additional magnetic can arrange electrons at the atomic and molecular level. The hydrocarbon structure loosens up, polarization and arrangement of molecules take place and when the South Pole polarization exists, the liquids get charged positively.

Quality Safety & Assurance

The Maximizer is manufactured to the highest standards of quality and undergoes a regular and scrupulous quality control by our own and independent third-party QC teams.

Our proprietary monopolar fluid treatment technology has been developed into a complete product line. It insures proper application for treatment of liquid or gas media in common size circular conduits of varying material. The components for this device are 100% designed from the highest quality, state-of-the-art materials only.

The Maximizer also fulfills the fire safety norms as not readily flammable, very safe, and non-hazardous to people, animals, electronic equipment and the environment when properly installed.

Its patented metal screen prevents the dispersion of the magnetic field outside the pipe diameter and doesn’t need energy supply. The Maximizer is sold with a 10-year warranty against power loss. We warrant our device on its strength and will unconditionally replace them, at no charge, if it loses power.

The Maximizer can be safely applied with no harm to vehicular engines, generators, boilers, chillers, cooling towers, heat exchangers and evaporative condensers, with the primary benefits of energy conservation and emissions reduction.

To learn more about the Maximizer or to place an order, contact us at or 1-888-626-3037